In 2021, NSW became the second Australian state to ban the use of firefighting foam that contains perfluoroalkyl substances (PFAS). While the health effects of these substances on human beings are still being studied, they are known to be toxic to fish and some animals.

If you have fire extinguishers on your premises, you should check whether they contain PFAS, and if so, make a plan to replace them.

PFAS: what are they?

PFAS are a class of manufactured chemicals that have been in use since the 1950s to make products designed to resist heat, stains, grease or water.

In 2017, the ABC’s Four Corners programme revealed that PFAS-containing firefighting foams had contaminated soil and groundwater at a number of Australian Defence Force facilities.

According to the Australian Department of Health, this kind of contamination is of concern ‘because these chemicals are highly persistent, have been shown to be toxic to fish and some animals, and can accumulate in the bodies of fish, animals and people who come into contact with them’.

NSW regulations ban PFAS in firefighting foam

The NSW Government has taken the initiative to ban the use of PFAS-containing firefighting foam, except in fighting catastrophic fires or where there are special exemptions.

NSW became the second jurisdiction in Australia to introduce a ban on use of fluorinated foams, after South Australia introduced a similar ban in 2018. The NSW Government described the changes as a key step for the state towards achieving the objectives agreed in the National PFAS Position Statement prepared by federal, state and territory governments.

What you can do now

Most businesses have fire extinguishers on site. If you’re in NSW, now is the time when you should be reviewing your fire extinguisher program, and making a plan to replace any PFAS-containing products.

If you manage an industrial facility in NSW with firefighting training grounds, you should review your use of PFAS-containing products now.

Wherever you are in Australia, regulations around PFAS are being regularly reviewed by state and territory governments and EPAs. Make sure you keep up to date so you don’t miss any changes.

How Airsafe can help

Appropriate management, storage and disposal of PFAS can be complex. Airsafe can help your organisation by conducting a risk assessment and advising on the steps you should take, following the framework set out in the PFAS National Environment Management Plan 2.0.

For help managing PFAS, call Airsafe today on 1300 888 338.

We’re delighted that the Airsafe website won a 2021 Australian Web Award, in the category of Medium Business.

The Australian Web Awards recognise the best in the Australian digital industry. An expert panel assesses entries on the basis of design, usability and accessibility, and only the best emerge as winners.

Designed and developed by our friends at Humaan, our winning website is all about making our services easier to find and understand, especially as our business has expanded nationwide and our service offering has diversified.

We know many of our customers are in a hurry and a lot of our visits to our website come from mobile phones. So we’ve focused on giving everyone a smooth, easy to use experience, no matter what device they’re using.

We’re delighted with the award, and we thank Humaan for their hard work and the brilliant result.

Welding can generate fumes and ultraviolet (UV) radiation, both of which have been linked to cancer. Welding fumes can cause lung cancer, and are linked to kidney and bladder cancer if safety precautions are not taken. Welding-related UV radiation can cause melanoma.

In 2017, the International Agency for Research on Cancer (IARC) (a branch of the World Health Organization) determined there was sufficient evidence to upgrade welding fumes’ carcinogenic status, and to classify UV radiation for the first time. They made the following changes:

- changing welding fumes’ carcinogenic status from Group 2B Carcinogen (possibly carcinogenic to humans) to Group 1 Carcinogen (carcinogenic to humans)

- classifying UV radiation emitted during welding as a Group 1 Carcinogen.

How welding generates fumes and UV radiation

Fumes, mists, dust, vapours, and gases, including ozone, can all be generated during welding. Some are visible, but many are not.

The amount and form of fumes emitted depends on the process and materials used in welding. Different metals, solvents, flux, paint, and plastics can all generate different fumes.

UV radiation comes from electric arcs generated during arc welding. The amount of UV radiation generated is significant; it can travel long distances from arcs, especially in reflective environments; and it can produce large amounts of ozone.

Welding fume obligations under existing legislation

Under the Model WHS legislative framework, employers or persons conducting a business or undertaking (PCBUs) have the responsibility:

- to ensure welders are not exposed to health and safety risks during the course of their work activity, as far as is reasonably practicable

- to effectively manage the risks of hazardous chemicals, airborne contaminants, and plant, as well as other welding-related hazards such as noise and manual tasks

- to consult with their workers about the health and safety risks associated with welding activities and the development and implementation of appropriate controls.

Workplace Exposure Standard may be lowered

Safe Work Australia (SWA) has proposed lowering the Workplace Exposure Standard (WES) for Chromium VI from 0.05 mg/m3 to 0.000007 mg/m3 (7 ng/m3).

If this new, significantly lower WES is adopted, it will have a number of implications for the measurement and assessment of welding fume.

Specific hazards and control measures

To determine the risk of fume exposure while welding, you must first determine what equipment and materials are being used, as well as the amount of fumes, dust, vapour, and gases generated.

For example, when steel that has been coated with a rust-proofing compound is welded, phosphine is produced. Phosphine gas in high concentrations irritates the eyes, nose, and skin and has the potential to cause harm to lungs and other organs. To avoid phosphine contamination in this situation, you will first look for rust-proofed steel in the material to be welded.

Whatever materials you’re working with, Airsafe can help you determine the appropriate control measures.

How else can Airsafe help?

Airsafe’s experienced occupational hygienists can:

- consult with employees and provide them with information and training on the new findings and updated health risks

- consult with employees to develop and implement risk management and health monitoring requirements

- review current workplace risk assessments, controls, and PPE requirements using updated safety data sheets (SDS) and technical information from suppliers

- conduct air monitoring to measure exposure to welding fumes.

Avoid risking your team’s health: call Airsafe on 1300 810 796 .

In 2021, Airsafe was surprised to get a call from the Dr Phil show. An Australian couple believed they were being poisoned by their neighbours, with serious effects on their health. Dr Phil wanted us to use our expertise in air quality and hazardous materials to find out whether their belief was justified.

Over the years, Airsafe has been hired for many different reasons, but this was a new one! Nevertheless, we knew we were the right people for the job, and we sent our senior occupational hygienist Josh to investigate. Here’s what he found:

The work we did for Dr Phil was similar to any comprehensive site assessment. It included:

Walkthrough inspection around the property

- Thorough consultation with the client to ascertain specific requirements

- Detailed investigation of the air quality through a variety of testing, such as general respirable dust, volatile organic compounds, polycyclic aromatic compounds, asbestos, lead, hexavalent chromium, silica, indoor and outdoor dust

- Air samples, microbiological testing

- Surface testing for a variety of sources such as particulate, spores, microbiological contaminants, asbestos, lead

- Soil testing for a variety of substances

- Preparation of relevant Inspection Reports.

In total, our air quality assessment included 280 separate tests.

So what was the outcome? After a comprehensive chemical analysis, Airsafe determined that the house was not being contaminated by chemicals from the neighbour. But that didn’t mean the couple’s illness was imaginary. Something was making them sick, but it was coming from inside their home: black mould.

There are many reasons for bad air quality

This couple’s experience shows how air quality issues can have many different sources, and it’s not always the one you expect.

Poor air quality can be the result of natural events like bushfires and dust storms, or it can come from human activity like:

- consumption

- waste disposal

- industrial production

- transportation

- energy generation.

As well as microbiological contaminants like black mould, air can be contaminated by excessive quantities of chemicals like carbon monoxide, or by particulate matter.

If you suspect an air quality issue in your home or workplace, Airsafe can conduct a full air quality assessment – as we did for the Dr Phil couple – to determine the source of any contamination, and give you reliable advice on any steps you should take to decontaminate the building and avoid risks to your and others’ health.

Talk to Airsafe about an air quality issue: call us on (02) 9555 9034.

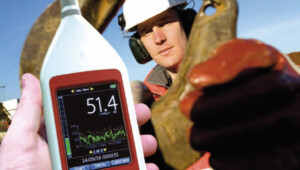

During construction, the use of heavy machinery may cause noise and vibration. Exposure to this noise and vibration can carry health risks for workers.

With our many years of expertise in occupational hygiene, Airsafe can measure noise and vibration levels with complete accuracy, and advise you on the best way to mitigate any risks.

Noise

Noise can be either airborne or ground-borne.

Airborne noise may be continuous, impulsive or intermittent, and may contain high pitch or low dominating tones. The perception of noise by people, animals and environments can vary widely. It depends upon many factors including frequency. Airborne noise is measured by a sound meter using the decibel scale.

Ground-borne noise is noise heard within a building that is generated by vibration transmitted through the ground into a structure. It is typically heard as a low frequency rumbling. It’s often referred to as “regenerated noise”. Ground-borne noise is also measured by a sound meter.

The impact of noise depends on its source and the proximity of the receiver. Different people have different reactions and sensitivities to noise.

The amount of noise generated by construction activity depends on the site and the type of work. For instance, noise levels from above ground activities such as demolition and removal of excavated material will be different to noise from those associated with underground activities such as tunnelling.

Where required, noise monitoring equipment can be installed to monitor noise levels, so their impact can be mitigated if they are too high.

Vibration

Construction vibration is usually measured as vibration velocity (Peak Particle Velocity in mm/s) using an accelerometer or geophone. Vibration Dose Value is a metric used to accumulate vibration energy over a day or night time period to determine its impact on human comfort.

People and other receiver types (that is, animals or environments) are often sensitive to vibration. They may be able to detect vibration at levels well below the amount that causes building damage.

Health effects of combined noise and vibration

There is evidence that workers who use vibrating plant and are exposed to noise at the same time are more likely to suffer hearing loss than workers exposed to the same level of noise alone. Exposure to both vibration and noise is also understood to increase musculoskeletal problems.

Employers should consider measures to eliminate or minimise exposure to whole-body:

- at the source of vibration (most preferred)

- along the paths of the vibration

- at the position where the vibration enters the worker (least preferred).

Consider if hazards from using vibrating plant can be completely removed from the workplace, for example by introducing remotely controlled mobile plant rather than plant driven by workers.

Exposure standards for noise and vibration

For noise exposure, Airsafe recommends that the internal construction noise levels should be based on the ‘maximum’ internal levels presented in the NSW Work Health and Safety Regulation 2017 Part 4.1.

The vibration dose values recommended in Assessing Vibration: a technical guideline (DEC, 2006) (derived from British Standard 6472) should be followed when completing vibration monitoring.

Guidelines for minimising noise and vibration

Here are some general guidelines for minimising issues with noise and vibration during construction:

- Minimise metal-on-metal contact: Bins, skips and chutes can be lined with material such as carpet, which helps deaden the sound of metal and other waste disposal.

- Avoid dropping items from a height: When an item is dropped from a height, the resulting noise is louder than if it were put in place directly.

- Use equipment sensibly: Turn off equipment when not in use. Throttle settings should be reduced if possible.

- Encourage appropriate staff conduct: Staff should not use loud radios or stereos outdoors during sensitive times, such as early in the morning in a residential area. Shouting and slamming vehicle doors should be avoided.

- Use PAs appropriately: If a PA is on site it should be used sensibly and in moderation. Avoid broadcasting telephone calls through the PA.

- Manage truck noise: Noise from trucks is a common issue, especially near residences. Scheduling and management of truck movements is important to reduce issues associated with reversing beepers, engine noise and general off-site activity.

How Airsafe can help

Evaluating problems arising from noise and vibration requires a qualified professional, such as one of Airsafe’s occupational hygienists, to perform accurate measurements and analyse the results.

Airsafe measures sound levels using a sound level meter or a noise dosimeter that complies with Australian Standards. We ensure worksites comply with all state and local regulations. And we give you reliable advice on mitigating any possible health risks to your people.

To talk about a noise or vibration issue, call Airsafe on (02) 9555 9034.

In 2021, New South Wales introduced changes to exposure standards that affect companies and workers in the mining industry. From 1 February 2021, the exposure standard for coal dust in mines was reduced, while an exposure standard for diesel particulate matter was introduced for the first time.

The updated exposure standards are:

- Coal dust: TWA (time-weighted average) of 1.5 mg/m3 (previously 2.5mg/m3)

- Diesel particulate matter: TWA of 0.1 mg/m3 (measured as sub-micron elemental carbon).

NSW was the first jurisdiction in Australia to implement a standard for diesel emissions in the mining sector. This came about because of an increased risk of exposure to accumulated exhaust in underground mines.

Risks of coal dust

Coal miners are at risk for respiratory diseases caused by dust from mines. When inhaled, coal dust remains in the lungs. Long-term exposure can cause coal mine dust lung disease (also known as black lung disease). Miners with combined exposures to coal and crystalline silica dust can also get mixed dust pneumoconiosis.

These diseases cannot be cured, so prevention is critical.

Risks of diesel emissions

There is growing awareness of the risks of exposure to diesel exhaust in the mining industry.

Diesel exhaust emissions contain a complex mixture of gases, vapours, aerosols and particulate matter. Most mines use diesel engines in some form. Underground miners are exposed to concentrations of diesel particulate matter significantly higher than those in any other occupation.

Controlling diesel emissions: your obligations

All mines should have a documented strategy to control diesel emissions, to minimise people’s exposure as much as possible. This forms part of your obligations under

the Work Health and Safety (Mines and Petroleum Sites) Regulation 2014.

You should do a risk assessment to help you identify and control areas and tasks where workers may be exposed to diesel exhaust. Start with a risk assessment:

- identify areas of exposure risk

- audit site practices

- review and monitor risk control measures to ensure compliance with the exposure limit and maintenance of low atmospheric concentrations.

As part of the risk assessment process, you should consider workplace practices, training and culture:

- worker training on driving behaviour and effect on emissions

- maintaining awareness of best practice methodologies and new technological innovations

- use of appropriate respiratory protective equipment

- workplace area atmospheric monitoring and ventilation monitoring.

Some practical steps you can take to minimise diesel emissions include:

- controlling diesel exhaust emissions at the source

- use of low emission diesel engines

- emission reduction devices (particulate filters, catalysts)

- use of low emission fuels and quality lubricants

- provision of air conditioned (filtered) operators’ cabins

- control of diesel engines in areas of identified risk

- minimising the number of diesel engines operating at same time.

- robust maintenance and exhaust gas emissions testing

- controlling exposure to airborne diesel emissions

- good ventilation strategies and systems

Air monitoring for diesel particulate exposure

Air monitoring for diesel particulate exposure

Air monitoring is a particularly important measure in controlling the risk of diesel particulate exposure. It’s one of your obligations under clause 50 of the Work Health and Safety Regulation 2017.

How often to conduct monitoring, and what methods to use, depend on the risk. You should especially consider:

- monitoring people who are more likely to be exposed to diesel particulate

- monitoring over a range of standard operational processes as well as exposure which occurs during abnormal mining operations

- static positional monitoring to determine airborne concentrations of diesel particulate matter, and the effectiveness of implemented control measures.

Air monitoring samples must be collected in accordance with Australian Standard sampling methodologies under the direction of a suitably competent Occupational Hygienist independent to the mine, with subsequent analysis undertaken by a NATA accredited laboratory using the NIOSH Method 5040.

How Airsafe can help

We analyse baseline airborne dust exposure

As experts in air quality monitoring, Airsafe knows how to conduct an effective air monitoring program, beginning with placement of equipment, which is critical to the overall sampling strategy and interpretation of results. We use two different air monitoring methods:

- Personal dust monitoring, where the air monitoring equipment is attached to the worker, with the sampling device within the breathing zone to estimate the exposure. The exposure is then compared against the exposure standard.

- Static dust monitoring, collected using air equipment to assess the concentration of dust released into the air by processes, or to assess the effectiveness of controls such as local exhaust ventilation (LEV).

We create a comprehensive health control plan

All mines, quarries and petroleum sites are required to develop and implement a health control plan. A health control plan sets out how the operator will manage the risks to health associated with their mining or petroleum operations, as required by clause 26 of the Work Health and Safety (Mines and Petroleum Sites) Regulation.

Airsafe has many years of experience creating health control plans. We can help you make sure this important document is legally compliant.

We provide guidance for ongoing monitoring and analysis

Monitoring of a worker’s health is legally required when the hazard has the potential to exceed exposure limits, or when the level of risk from the hazard varies. Airsafe can guide you about the appropriate ongoing air monitoring and analysis program and help you to implement it.

We detail corrective actions

Where possible, you should always try to remove or eliminate hazards from the workplace, for example by using a different process, or changing the way a job is done.

Airsafe will help you determine the right corrective actions to control generation of and limit worker exposure to dust, so far as reasonably practicable.

For help controlling coal dust and diesel exposure, call Airsafe on (02) 9555 9034.

Mould inside a building can cause serious health problems, especially the toxic variety known as black mould. At Airsafe, we had a client who unfortunately left long-term mould issues untreated, resulting in a very serious illness.

Mould inside a building can cause serious health problems, especially the toxic variety known as black mould. At Airsafe, we had a client who unfortunately left long-term mould issues untreated, resulting in a very serious illness.

If you suspect you have mould in your home or workplace, get Airsafe involved, sooner rather than later.

What is black mould?

Stachybotrys chartarum, also known as black mould or toxic black mould, is a type of mould often found in damp or water-damaged buildings.

To grow, black mould needs very high moisture levels. These can be the result of flooding, leaking roofs, plumbing issues, or poor building maintenance. Black mould typically grows in materials like timber, plasterboard, wood framing, composite wood flooring, carpets, and carpet underlay.

How to identify black mould

The best way to identify black mould is by its smell and colour. Black mould has a mildewy or musty smell. True to its name, it’s distinctively black, whereas other mould species that grow in the house may be pink, grey, white or brown.

Black mould and your health

A number of symptoms can come from exposure to black mould, including:

- throat irritation

- eye irritation

- nasal and sinus congestion

- sneezing

- cough

- difficulty breathing

- chest tightness

- skin irritation.

Exposure to black mould may also cause heightened sensitivity, depending on the time and nature of exposure.

Black mould spores and associated toxins mainly cause harm via inhalation, ingestion, and contact. They can be spread through air, food, bedding or water, especially flood water.

The biggest health risks come from unusually high quantities and prolonged exposure. The condition known as sick building syndrome is often associated with black mould exposure.

At Airsafe, we know the risks of toxic mould

An example from Airsafe’s work shows what can happen if mould is left to grow.

One of our senior occupational hygienists inspected a house in Sydney’s affluent eastern suburbs to investigate a serious mould issue.

An unfixable broken water pipe under the house was causing high levels of moisture around the walls and floor surfaces. This was providing fertile ground for mould to grow, even though no water leaks were ever identified inside the house.

An occupant of the house had been experiencing allergies and skin conditions She eventually had to leave the house, and sadly has now been diagnosed with aspergillosis, a terminal illness associated with the mould in her house.

Toxic mould can be invisible and airborne. If anyone in your household or workplace suffers from asthma, a compromised immune system, breathing difficulties, or allergies, they are at risk of serious or fatal health problems if they are exposed to black mould over time.

How we assess buildings for mould

If you have any concerns about mould, the first step is to engage Airsafe for an assessment.

We begin with an inspection of the indoor environment. We survey the area for odours indicating mould or bacterial growth, moisture sources such as stagnant water or leaking pipes, and water-damaged building materials.

Air sampling is the most common way in which we assess mould levels, as it’s considered the most reliable way of assessing respiratory exposure to mould.

We sample both indoor and outdoor air comparing mould spore concentrations. If the indoor concentration is higher, or the mould is of different species, this can indicate an indoor hazard.

Where we suspect mould on a specific indoor surface, we conduct surface sampling. Surface sampling can also be used to identify the source of mould exposure.

How we solve a mould problem

Once we’ve identified a mould problem, we set about solving it.

Items that are beyond repair will require disposal. These might include porous items like mattresses, pillows, timber or plasterboard which may have absorbed quantities of mould and contaminated water.

Once the source of contamination has been found and stopped, drying will be required. This is important to prevent the mould from spreading more throughout the building. While drying is completed, it’s important avoid disturbing the mould spores and dust, which might cause them to re-enter the air inside the building.

With all the surfaces dried out, remaining items within the building will need cleaning with a damp wipe or A HEPA vacuum.

If mould spores have gotten into the air ducts and vents, they can circulate around the building inadvertently, so these areas need to be thoroughly cleaned as well.

Once all these actions have been taken, we complete a visual inspection and repeat air or surface sampling as required. New samples are sent to a laboratory for analysis before a clearance certificate is issued.

Concerned about mould? Call Airsafe on (02) 9555 9034 for an urgent assessment.