During construction, the use of heavy machinery may cause noise and vibration. Exposure to this noise and vibration can carry health risks for workers.

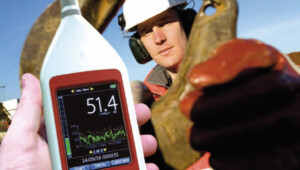

With our many years of expertise in occupational hygiene, Airsafe can measure noise and vibration levels with complete accuracy, and advise you on the best way to mitigate any risks.

Noise

Noise can be either airborne or ground-borne.

Airborne noise may be continuous, impulsive or intermittent, and may contain high pitch or low dominating tones. The perception of noise by people, animals and environments can vary widely. It depends upon many factors including frequency. Airborne noise is measured by a sound meter using the decibel scale.

Ground-borne noise is noise heard within a building that is generated by vibration transmitted through the ground into a structure. It is typically heard as a low frequency rumbling. It’s often referred to as “regenerated noise”. Ground-borne noise is also measured by a sound meter.

The impact of noise depends on its source and the proximity of the receiver. Different people have different reactions and sensitivities to noise.

The amount of noise generated by construction activity depends on the site and the type of work. For instance, noise levels from above ground activities such as demolition and removal of excavated material will be different to noise from those associated with underground activities such as tunnelling.

Where required, noise monitoring equipment can be installed to monitor noise levels, so their impact can be mitigated if they are too high.

Vibration

Construction vibration is usually measured as vibration velocity (Peak Particle Velocity in mm/s) using an accelerometer or geophone. Vibration Dose Value is a metric used to accumulate vibration energy over a day or night time period to determine its impact on human comfort.

People and other receiver types (that is, animals or environments) are often sensitive to vibration. They may be able to detect vibration at levels well below the amount that causes building damage.

Health effects of combined noise and vibration

There is evidence that workers who use vibrating plant and are exposed to noise at the same time are more likely to suffer hearing loss than workers exposed to the same level of noise alone. Exposure to both vibration and noise is also understood to increase musculoskeletal problems.

Employers should consider measures to eliminate or minimise exposure to whole-body:

- at the source of vibration (most preferred)

- along the paths of the vibration

- at the position where the vibration enters the worker (least preferred).

Consider if hazards from using vibrating plant can be completely removed from the workplace, for example by introducing remotely controlled mobile plant rather than plant driven by workers.

Exposure standards for noise and vibration

For noise exposure, Airsafe recommends that the internal construction noise levels should be based on the ‘maximum’ internal levels presented in the NSW Work Health and Safety Regulation 2017 Part 4.1.

The vibration dose values recommended in Assessing Vibration: a technical guideline (DEC, 2006) (derived from British Standard 6472) should be followed when completing vibration monitoring.

Guidelines for minimising noise and vibration

Here are some general guidelines for minimising issues with noise and vibration during construction:

- Minimise metal-on-metal contact: Bins, skips and chutes can be lined with material such as carpet, which helps deaden the sound of metal and other waste disposal.

- Avoid dropping items from a height: When an item is dropped from a height, the resulting noise is louder than if it were put in place directly.

- Use equipment sensibly: Turn off equipment when not in use. Throttle settings should be reduced if possible.

- Encourage appropriate staff conduct: Staff should not use loud radios or stereos outdoors during sensitive times, such as early in the morning in a residential area. Shouting and slamming vehicle doors should be avoided.

- Use PAs appropriately: If a PA is on site it should be used sensibly and in moderation. Avoid broadcasting telephone calls through the PA.

- Manage truck noise: Noise from trucks is a common issue, especially near residences. Scheduling and management of truck movements is important to reduce issues associated with reversing beepers, engine noise and general off-site activity.

How Airsafe can help

Evaluating problems arising from noise and vibration requires a qualified professional, such as one of Airsafe’s occupational hygienists, to perform accurate measurements and analyse the results.

Airsafe measures sound levels using a sound level meter or a noise dosimeter that complies with Australian Standards. We ensure worksites comply with all state and local regulations. And we give you reliable advice on mitigating any possible health risks to your people.

To talk about a noise or vibration issue, call Airsafe on (02) 9555 9034.